Welcome to the The Johnson Space Center Amateur Radio Club (JSCARC) site. We are located at the National Aeronautics and Space Administration (NASA) Lyndon B. Johnson Space Center (JSC) approximately 25 miles southeast of downtown Houston, Texas. Our mission is to actively provide and promote STEAM outreach, emergency operations, mission support, and public service for NASA and the local communities.

NOTA NOTA NOTA NOTA NOTA NOTA

W5RRR is an active participant of NASA ON THE AIR (NOTA)

nasaontheair.wordpress.com

Bulletins:

o May 4 Aliens v. Astronauts Fun Run @ JSC <AVA announcement>

** Signup for Ham Radio support role <HERE>

News:

o JSCARC April Monthly Minutes posted

o New steel table supports installed in W5RRR shack thanks to KA5TBB

o A new IC-9700 Satellite Station is installed in the shack

Belton Hamfest April 2024

Belton- The biggest Hamfest in Texas didn’t disappoint. It’s been interesting to observe the ebb and flow of this Hamfest each year as different hams and vendors seem to have seasonal inventory and predilections! For ... Read more...

3-500Z Arcing

A bit off topic for the general group, but I wanted to share a video of an arcing 3-500Z tube and a tip in troubleshooting with shorted radios/amps.(Note: the 3-500Z is a very popular compact ... Read more...

Fox Hunt for JSC Student Intern Group

With a break in the weather, 4 intrepid student interns, Zane, Issac, Arthur, and Eric participated in a special JSCARC Fox Hunt held a the JSC Gilruth center on Sunday March 24. For this event, ... Read more...

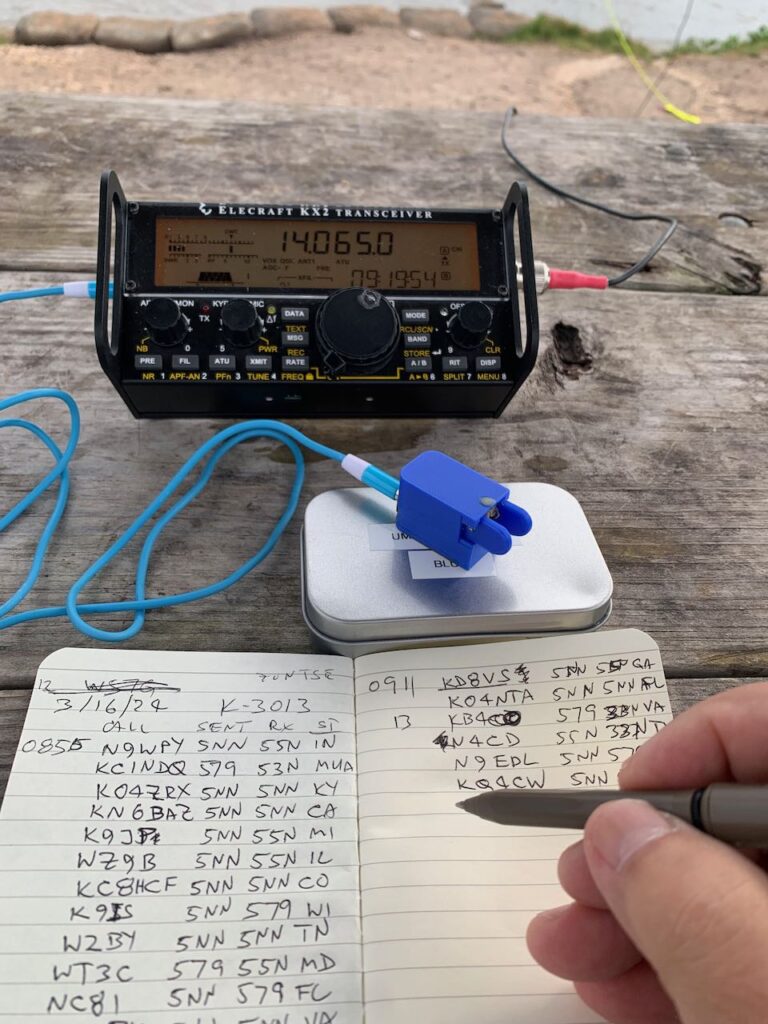

Lone Wolf JSCARC POTA #19 @ GISP

Due to sketchy weather and not much advance promotion/notice, the JSCARC POTA #19 was a one-person show by myself, W5OC. However, the weather behaved in spite of the harrowing thunderstorms earlier in the morning at ... Read more...

Greater Houston Hamfest Report

Ken K5RG acquired a table for the club at this year’s Greater Houston Hamfest. He, Carl WD5JRD, and W5OC anchored the JSCARC table from Friday afternoon through Saturday. The early opening of the hamfest on ... Read more...

Great report David! Would have loved to have been there! Thank you for your fortitude!